Edinburgh’s factories and plants impress not only with their output, but also with their immense ecological awareness. This is because they strive to keep pace with the general trend of environmental preservation. After all, as is well known, not only Edinburgh but all of Scotland is renowned for this. Numerous projects, exhibitions, and developments dedicated to ecology have long been a hallmark of these places. Discover more at edinburghname.

Even businesses producing goods seemingly far removed from the concept of ecology are committed to adhering to all regulations. They also develop engineering solutions that are not only innovative but also environmentally compliant. One such example is the North British Distillery Company.

The Genesis of a Traditional Drink Producer

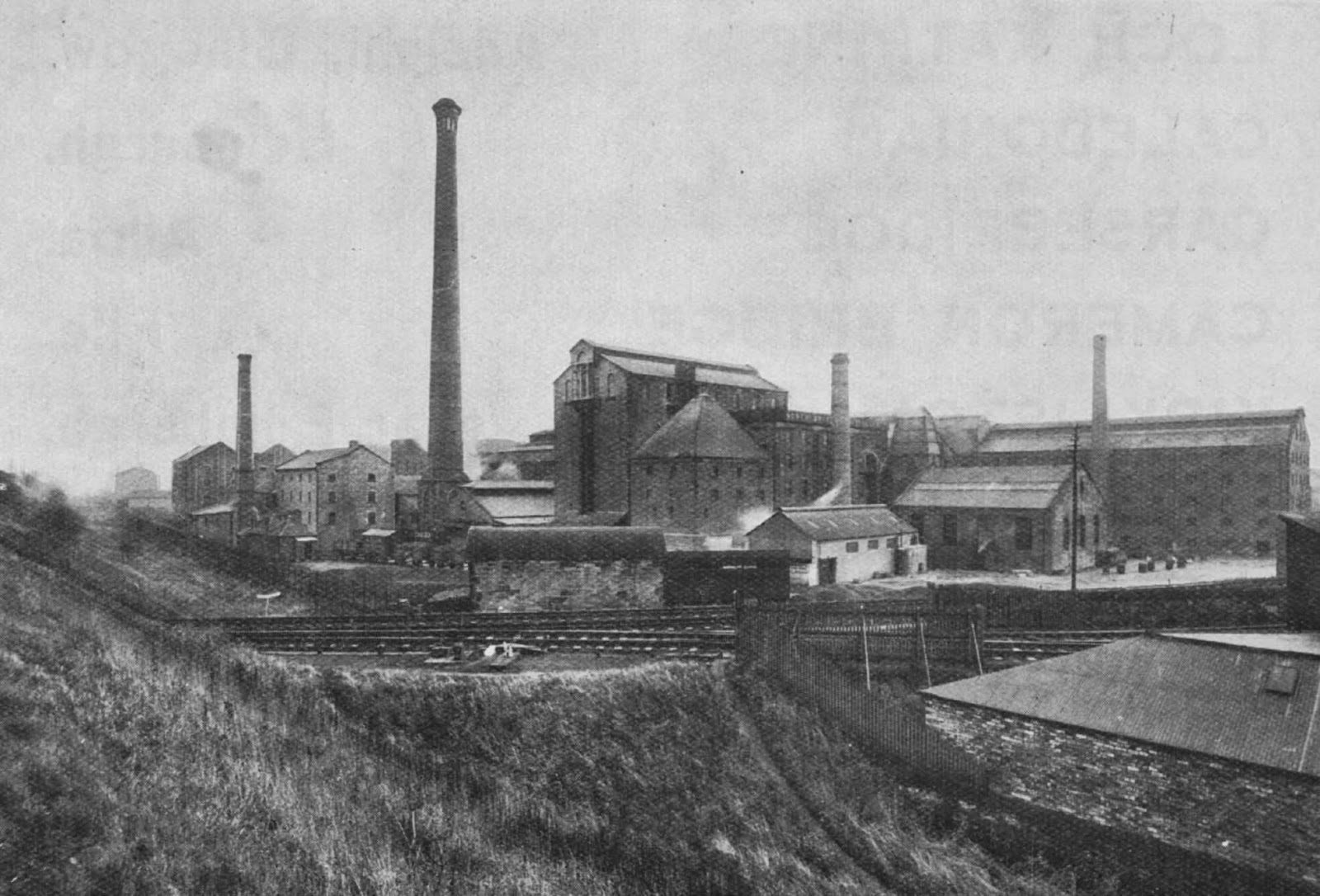

This unique distillery was established way back in 1885 by Andrew Usher, William Sanderson, and John Crabbie. The trio chose a site on the western outskirts of Edinburgh for their venture.

It’s important to note that all three were already successful whisky businessmen at the time. In 1885, by creating this new enterprise, they decided to combine their knowledge, efforts, and experience to build a new plant. Soon after, production of the traditional Scotch drink began.

Forced Pauses and Production Slowdowns

When the First World War broke out, the distillery halted its primary production and instead began manufacturing munitions. The long-term prospect for the plant at that time was linked to producing acetone for cordite. However, the war ended before this production plan could be fully implemented, so in 1920, the distillery returned to making its signature spirit.

But this normal operation didn’t last long. The Second World War led to the distillery’s closure in December 1939 due to a shortage of raw materials. The plant was only able to resume operations ten years later.

Understandably, this state of affairs significantly impacted production volumes, which plummeted and only began to recover in 1955.

Eliminating the Competition

When it comes to high productivity and substantial profits, competitors are often the main obstacle for any business. The North British Distillery Company certainly had its fair share, especially since whisky production has always been a true hallmark of Scotland.

However, in 1988, the distillery got lucky. That year saw the closure of another Edinburgh distillery, The Caledonian. North British Distillery Company confidently stepped in, becoming the city’s sole producer of this kind of spirit.

Structural Changes

Discussing the history of this enterprise wouldn’t be complete without mentioning another significant phase in its operations. At the turn of the 20th century, North British Distillery Company sold off many of its premises, including warehouses and maltings. Later, the distillery became jointly owned by Diageo Plc and The Edrington Group.

These changes undoubtedly benefited the company, as its production volumes significantly increased. By 2015, the distillery had reached a remarkable output of 2.5 billion litres of spirit.

Eco-Friendly Engineering Solutions

Delving deeper into the North British Distillery Company, one cannot overlook a crucial fact that highlights another equally important aspect of its operations: its commitment to environmental awareness and preservation.

Whisky production in Scotland is a highly regulated industry. Distilleries are not only obligated to comply with all established norms and laws, but their entire operation must also strictly adhere to environmental protocols. The North British Distillery Company has gone even further. In addition to rigorously meeting these requirements, the organisation has also adopted the practice of recycling waste residues. This has significantly reduced their waste disposal costs and, of course, contributed to environmental protection. Moreover, the distillery even receives a special subsidy under the green tariff scheme.

But the distillery hasn’t stopped there in promoting eco-consciousness among businesses. Through extensive studies and experiments, the North British Distillery Company has developed an ingenious engineering solution: utilising the heat generated by the main plant machinery’s engines. By connecting a waste heat boiler to the rear of the engine, the generated heat can be efficiently used in the distillation process.

Thus, the North British Distillery Company can quite rightly be considered one of the most significant players in Scotland’s alcoholic beverage industry. Beyond its impressive production figures, this enterprise sets a benchmark for environmental care. While demonstrating vast output, the distillery also actively implements new engineering developments that minimise harm to the environment.

Such an approach, you’ll agree, commands respect, especially considering that many modern businesses primarily focus on their own profits, with environmental concerns often an afterthought.